GETSBR - Advanced STP

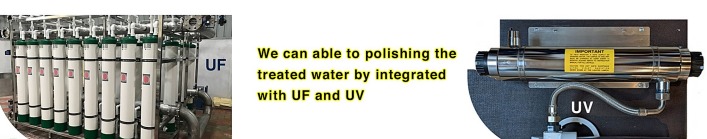

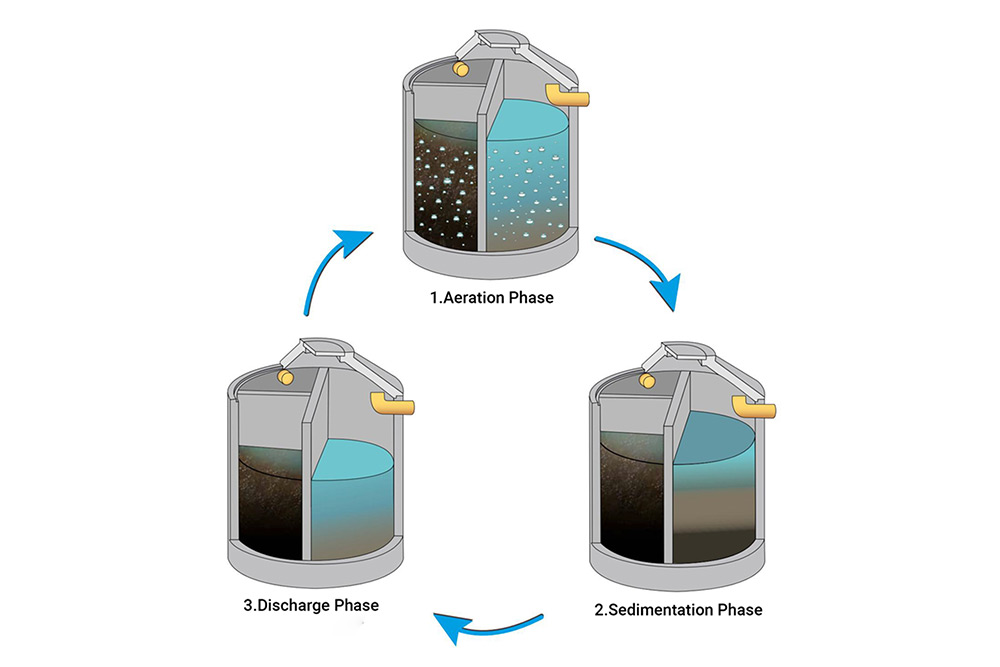

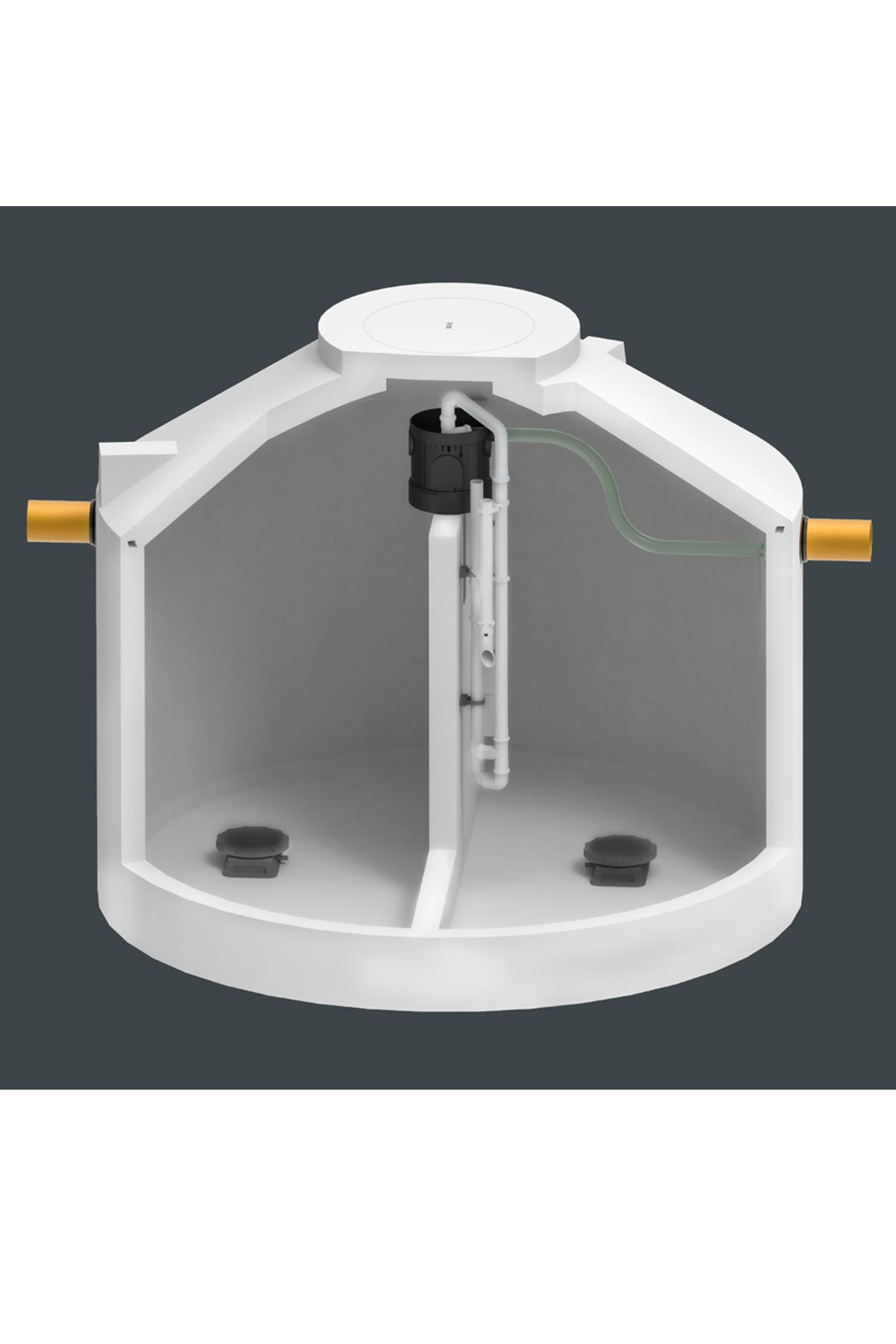

GRAM has recently launched the most advanced-fully automatic “GETSBR” wastewater treatment plant –the futuristic German technology with Indian Engineering that adopts sequenced batch reactor “(SBR) technology and consumes very less power when compares to other water treatment technologies.

Advanced Commercial STP

New generation of domestic sewage treatment plants

GETSBR – The proven solutions for fully automatic wastewater treatment

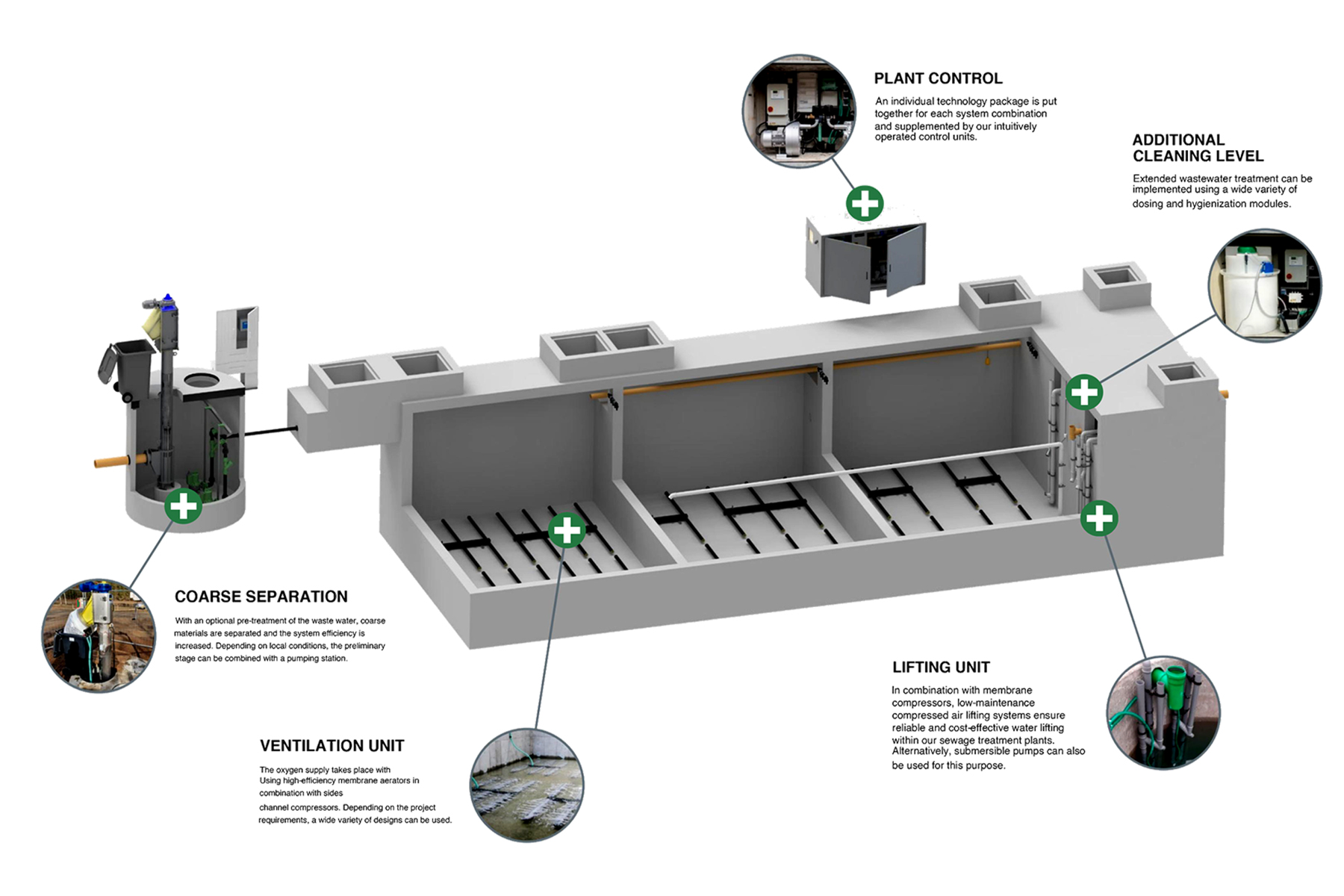

GRAM has succeeded in what has been tried for a long time-the small sewage treatment plant with almost no sludge removal approved and with outstanding cleaning performance. The Systems under the most varied conditions have proven over the recent years that work “without ifs and buts”.

“In Indian water, there is the principle that waste water is to be disposed of in such a way that well- the being of the general public is not affected. Also one decentralized wastewater disposal through small sewage treatment plants according to the Water Resources Act, the General serves well”

Only a few households in India are connected to underground drainage systems under city limits, and the rest of the rural & suburbs However, the sewer line connection is often not possible and inaccessible. The waste is to be eliminated in such a way that the valuable groundwater is not endangered. GRAM helps you with a smaller sewage treatment plant to a large sewage treatment system with robust technology instead of primitive septic tanks.

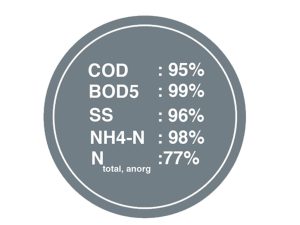

The treatment by GETSBR process when compared to conventional systems has a number of economic and technical advantages:

-

Title

Low energy Consumption (30% energy saving)

-

Title

No Manpower Required

-

Title

No pumps and Motors (Air lifting mechanism)

-

Title

No use of Chemicals & Consumables

-

Title

Zero O & M Maintenance Cost

-

Title

Zero Odour / Zero Noise

-

Title

Meets PCB Standard

-

Title

IoT enabled Systems (Fully Automated)

Note: Systems can be set up in the monolithic concrete round tank above and below ground levels. If installed above ground, an upstream pumping station is required. Matching units are available upon request. For a system design, please contact us!!